Process flow:

1. Broken

The natural stone materials after mining are uniformly and continuously sent to the coarse crusher (coarse jaw crusher) by a vibrating feeder for preliminary crushing. The produced coarse materials are transported by a belt conveyor to the cone crusher for further intermediate crushing;

2. Sand making

The crushed stone material is sieved through a vibrating screen to separate two types of stones. The stones that meet the requirements are evenly sent to the sand making machine for sand making processing, while those that do not meet the requirements are returned for re crushing;

3. Wash sand

Qualified sand is then sent to the sand washing machine (optional) for cleaning. The washed sand particles are transported by the conveyor to the finished material pile for packaging, producing various sand materials that meet the requirements.

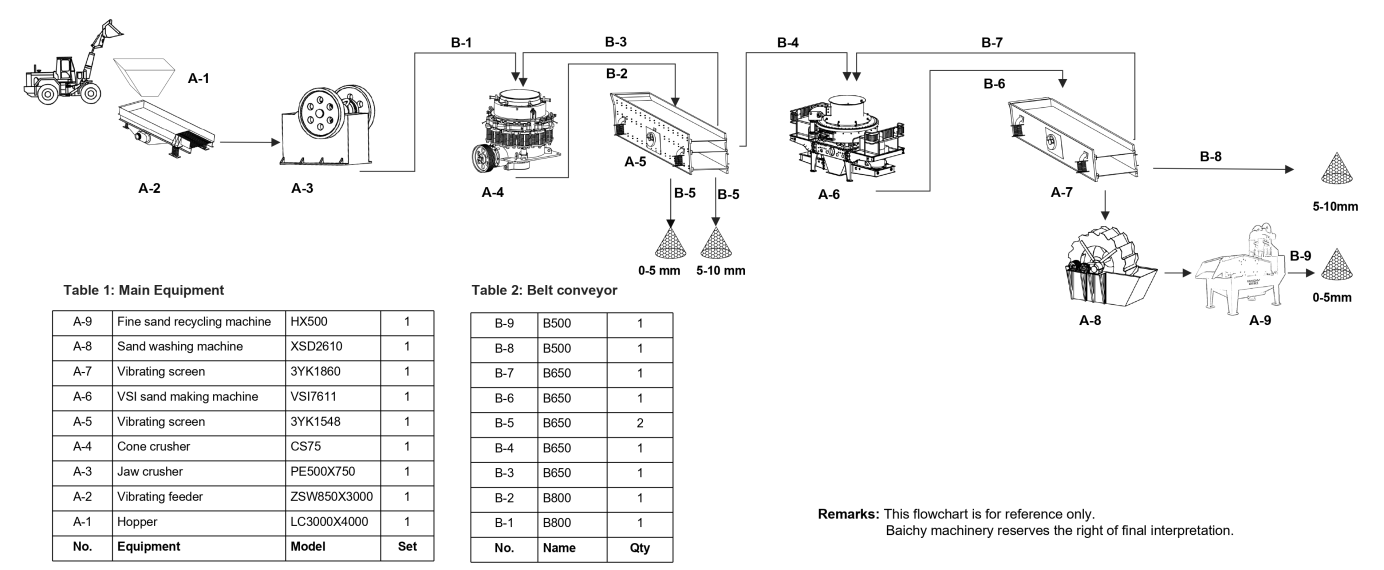

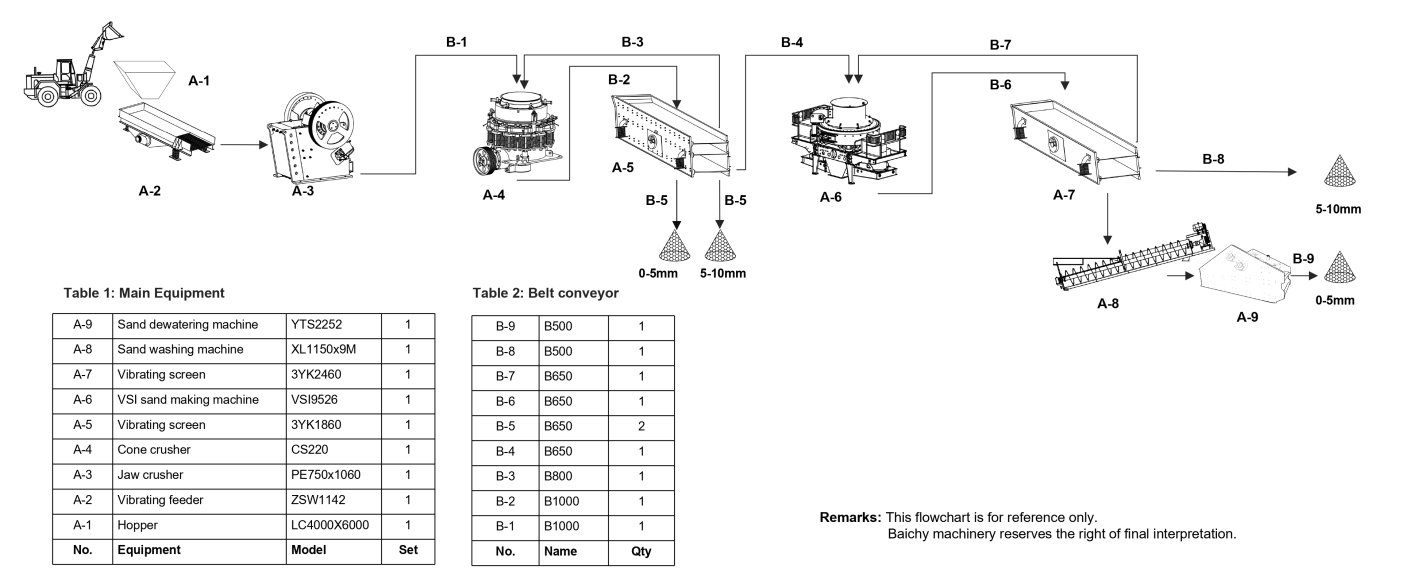

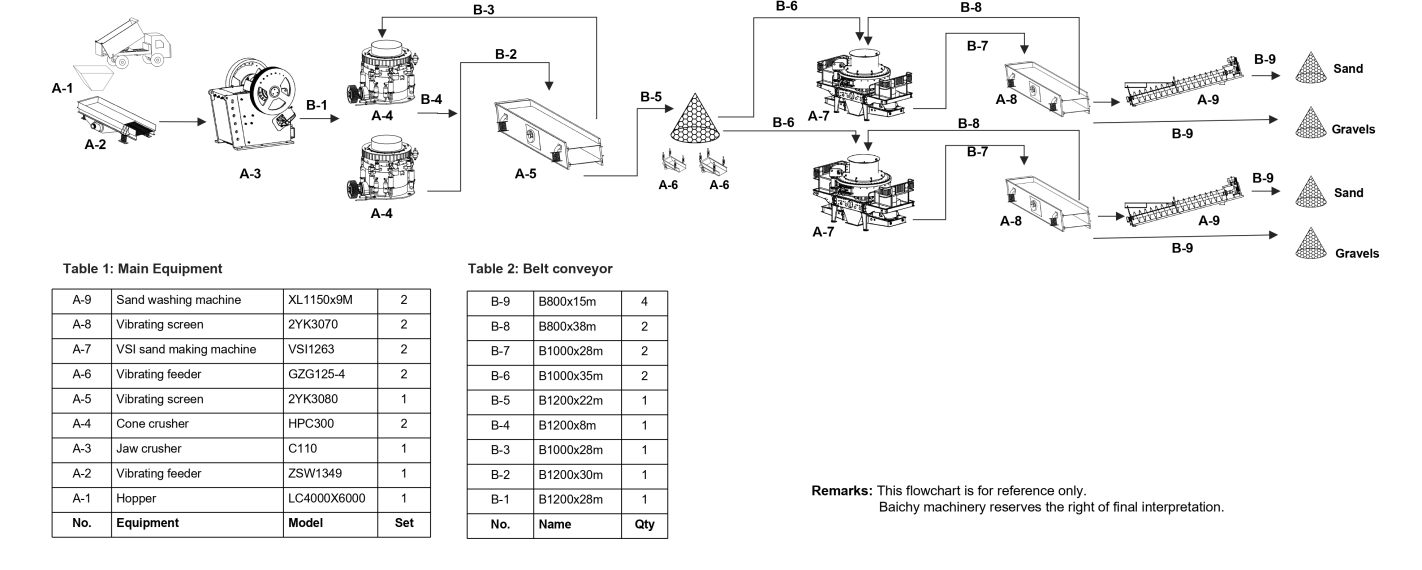

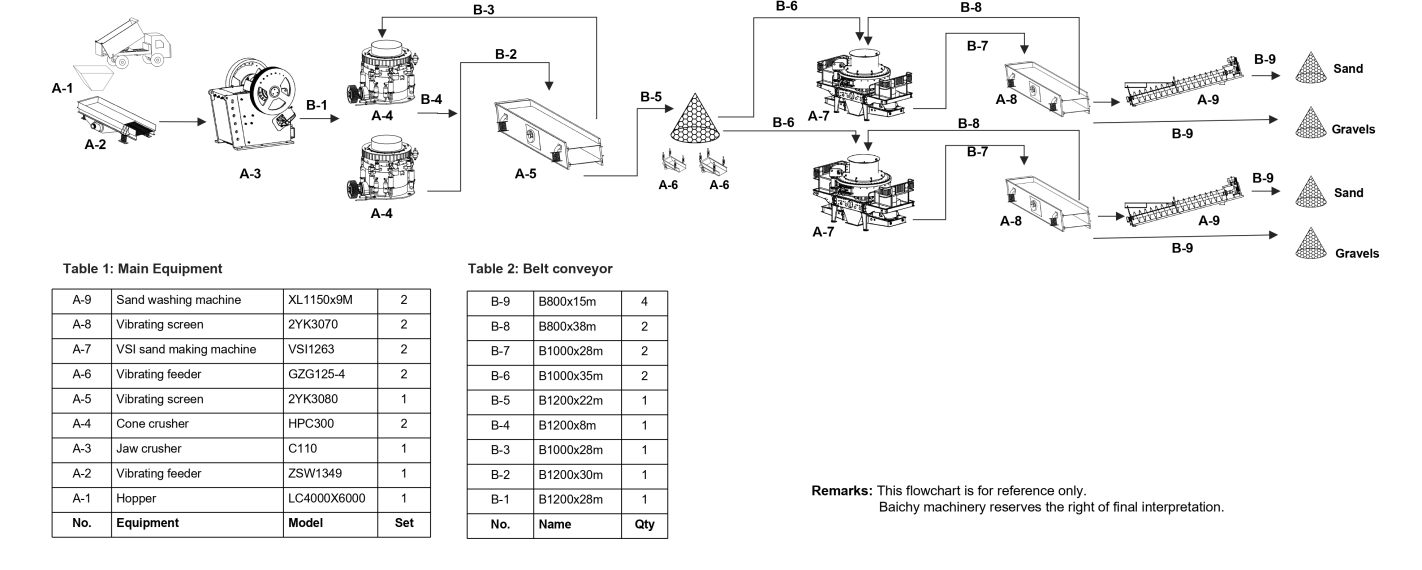

SAND MAKING PROCESS SCHEME

50-100 tph Sand making plant

150-250tph Sand making plant

100-150 tph Sand making plant

250-400 tph Sand making plant

Our services

EPC MASTER CONTRACT SERVICE

EPC contracting services effectively overcome the mutual restriction and disconnection of design, installation, construction and other links, so as to guarantee the quality of the project and provide customers with one-stop service.

Project Planning

Responsible for the overall planning and specific implementation of the entire project,the customer is only responsible for the overall,principle,target management and control.Most of the responsibility and risk is borne by our company.

Customized Solutions

Provide customers with a complete set of professional solutions to address their lack of understanding of equipment and other issues, making the project’s needs and positioning clearer. At the same time, it also allows customers to have a more concentrated range of equipment choices, reducing costs such as precision and finance.

Strictly Control Important Links

Our company is fully responsible for the design, production, installation, trial operation and other aspects, achieving full process control of each link. Customers can monitor the progress of the project in real time, ensure project quality, and greatly shorten the construction period.