Introduction

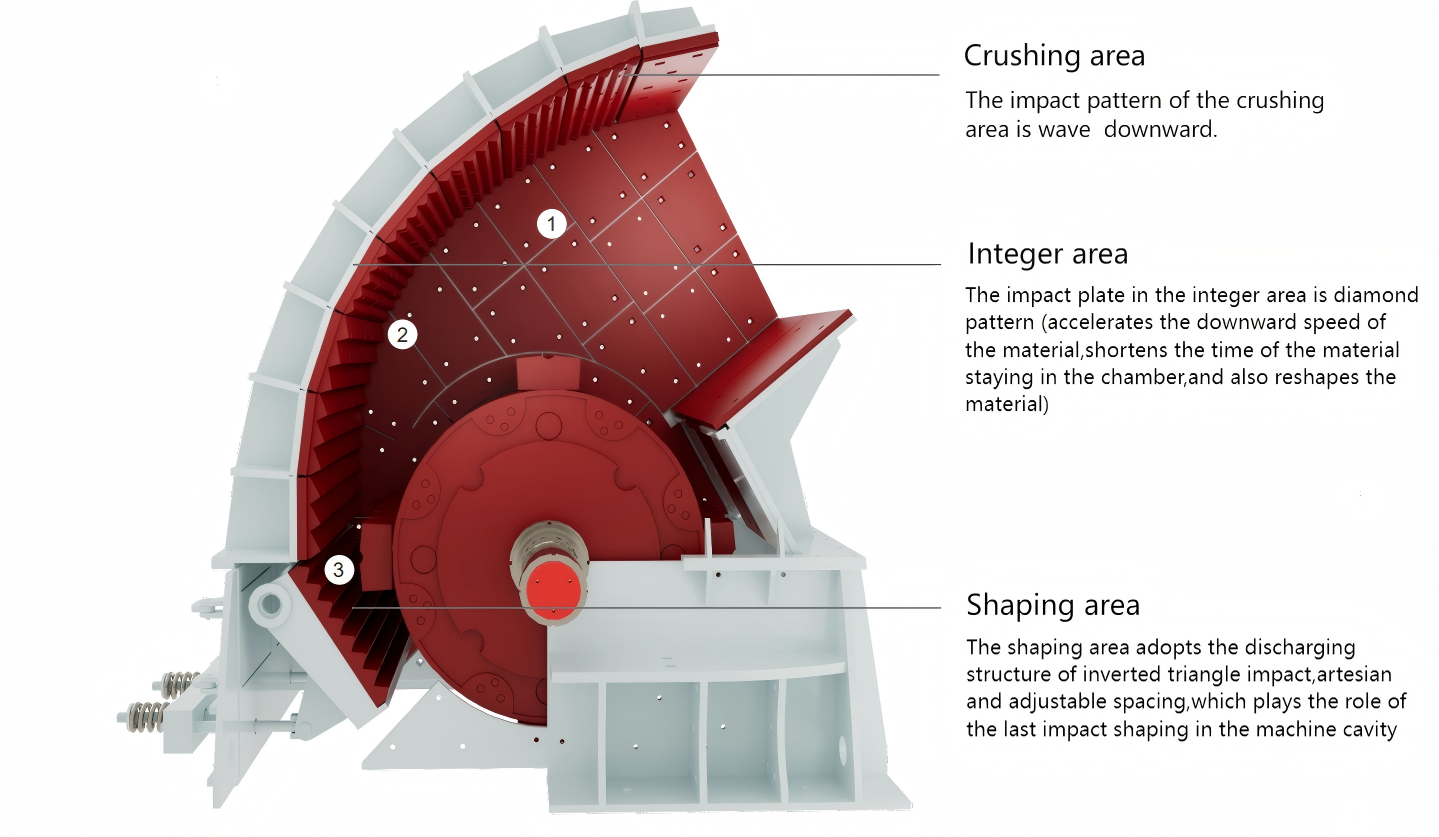

The core component of a hammer crusher is a rotor with multiple hammer heads, which is driven by a motor to rotate at high speed (usually 750-1500r/min). After entering the crushing chamber from the feeding port, the material is crushed by the strong impact, striking, shearing, and grinding of the high-speed rotating hammer head. After the crushed material reaches a certain particle size, it is discharged through the sieve holes of the lower sieve plate; Materials that have not reached the particle size will continue to be crushed by hammer impact in the crushing chamber until they meet the requirements.

Advantage

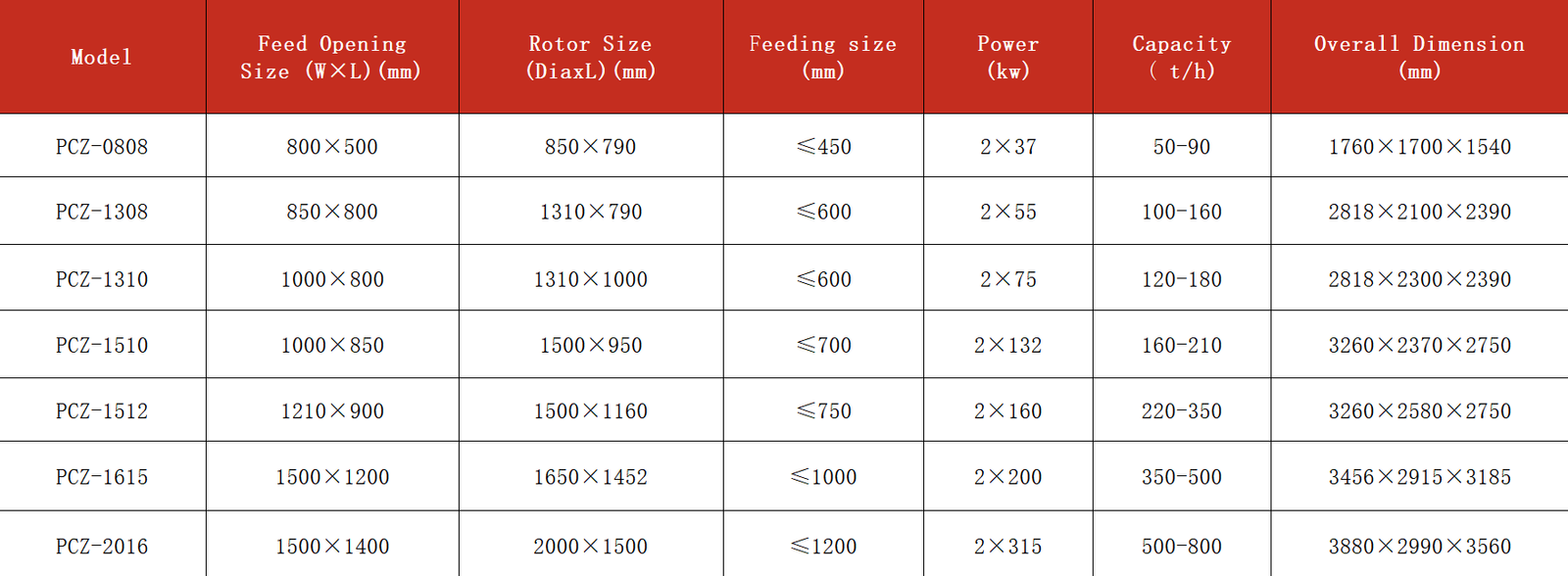

- The feed size of the hammer crusher can reach 750mm, and the output of a single hammer crusher can reach 3,000 tons.

- Heavy-duty hammer crushing and large feed particle size,small discharge particle size, one-time molding system.The discharging size can be adjusted can be adjusted according to customer requirements to meet different needs.

- Heavy hammer crusher adopts the most sophisticated accessories, especially the selection of wear-resistant parts. The hammerhead is the most advanced technology and the most wear-resistant metal in China.

Our Product

Export Globally