Introduction

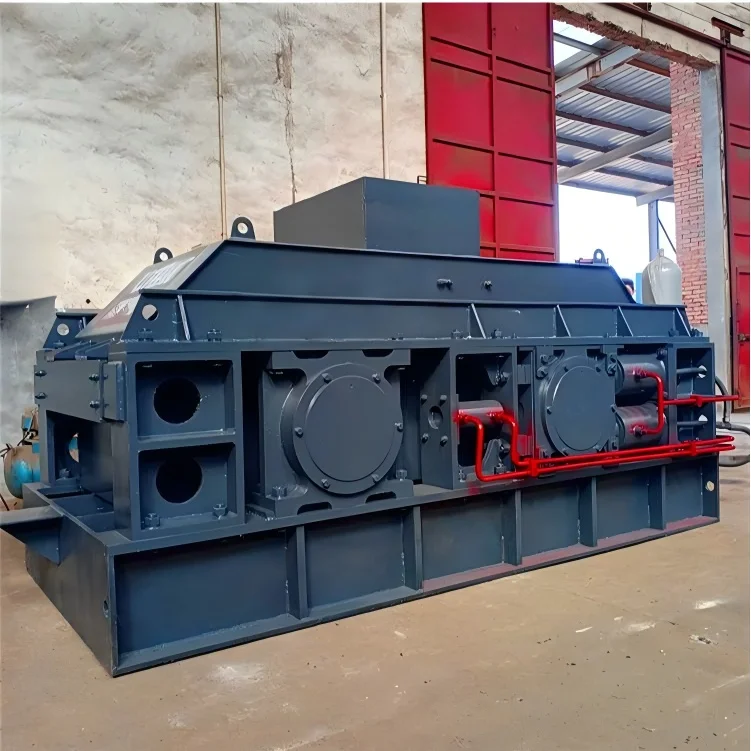

The roller crusher mainly completes crushing through two parallel and relatively rotating roller shafts (moving roller and fixed roller). The material enters between two rollers from the feeding port and is crushed under the squeezing, shearing, and grinding action of the rollers. The crushed material is discharged from the gap between the two rollers due to gravity or centrifugal force. By adjusting the gap between the two rollers, the size of the discharge particle can be controlled (the smaller the gap, the finer the discharge)

Advantages

- The particle size of the discharge is adjustable to meet a variety of needs.The smaller the gap, the more the discharge meets the crushing requirements of various speciÞcations and materials.

- Stable, high-yield, non-clogging, small size, small footprint, and investment savings.The structure is simple and has little maintenance, and the particle size of the discharge can be quickly adjusted by handwheel or hydraulic structure.

- The whole machine adopts a fully automatic lubrication system and is made of high-strength and high-quality steel, which makes the operation and maintenance of the machine safer and more secure.

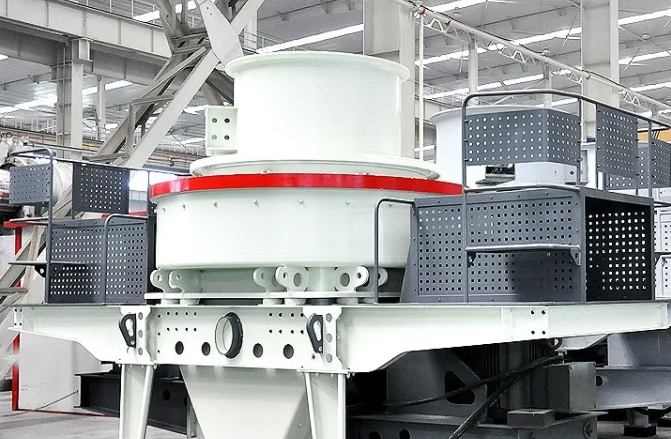

Our Products

WHY CHOOSE US

Export Globally